Pilot Cases

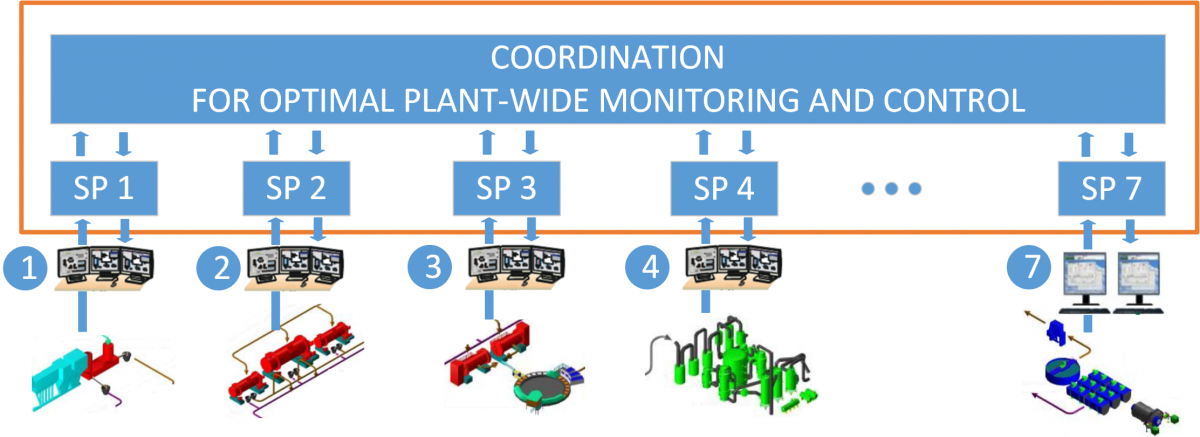

The COCOP developments will be demonstrated in two pilot cases:

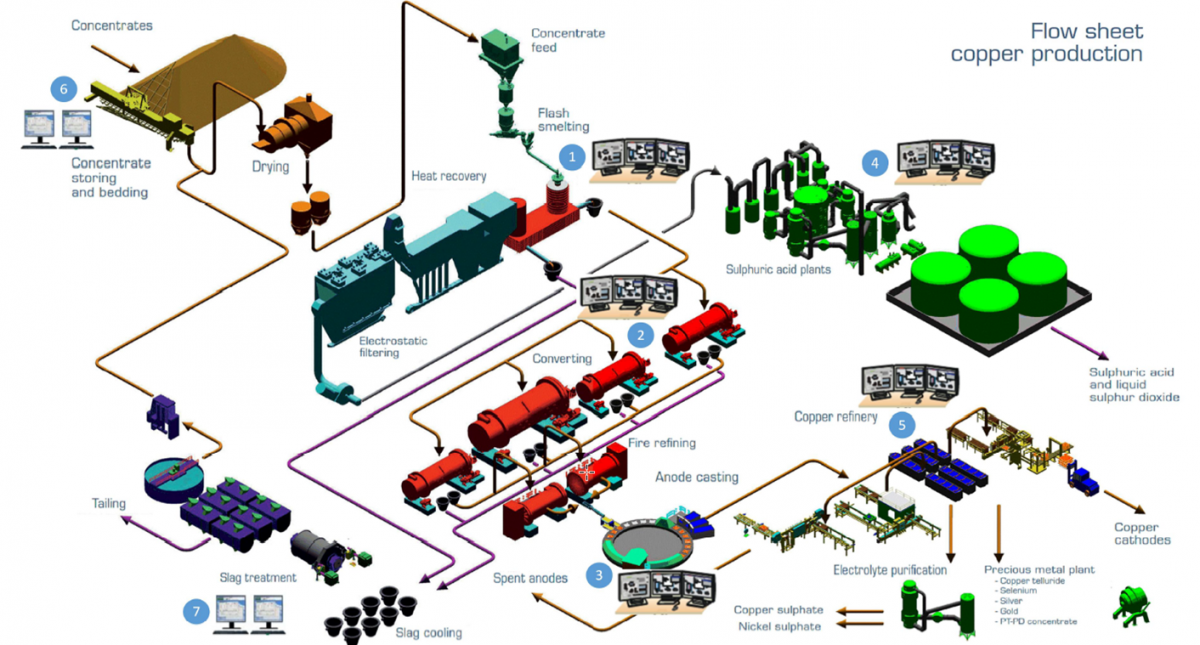

- Copper-smelting pilot case: the optimization will comprise of converter and anode-furnace scheduling, and setting target matte grades and feed rates of flash-smelting furnaces. Detailed advisory tools will be implemented for controlling unit processes to improve factors such as temperature, slag chemistry and impurities. The prototype will be installed in the Boliden Harjavalta copper smelter plant.

|

|

Flash Smelting Furnace

|

|

|

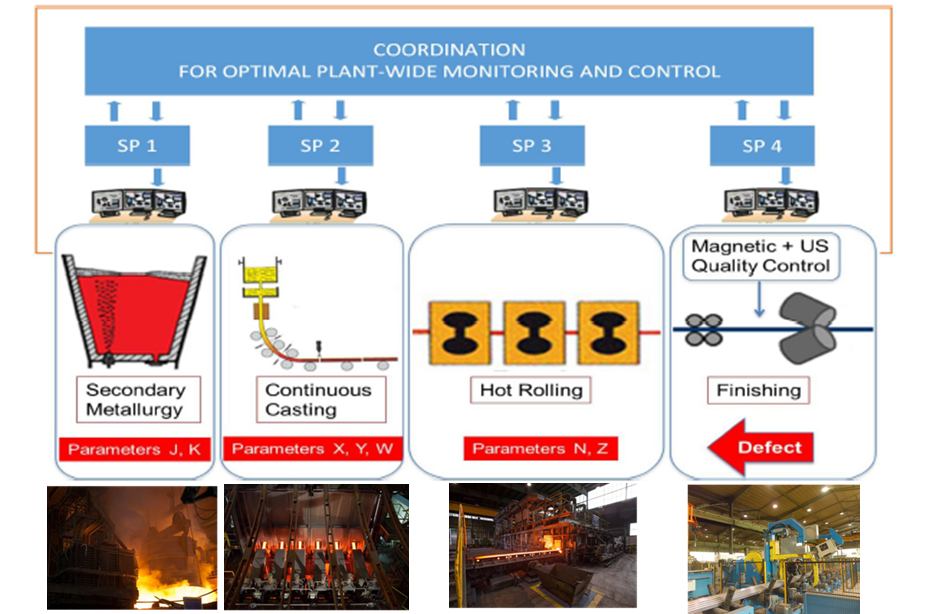

- Steel pilot case: developing of a steel manufacturing plant-wide monitoring and control tool in order to reduce the surface and sub-surface defects in micro-alloyed steels in as-rolled state. The subprocesses to be analysed will be those where the origin of defects may be: Secondary metallurgy, continuous casting and hot rolling. The prototype will be installed in the Bausauri plant of SIDENOR.