Home

COCOP is a European project under the Horizon 2020 framework and the SPIRE initiative

The need: process industry faces a strong need to increase product quality and reduce operating costs and environmental footprint. A complex plant comprises continuous and/or batch unit processes. The plant’s complexity stems from its dynamic properties, so a plant-wide monitoring and control is a requirement for achieving economically and environmentally efficient operation.

The vision: complex process industry plants will be optimally run by the operators with the guidance of a coordinating, real-time optimisation system.

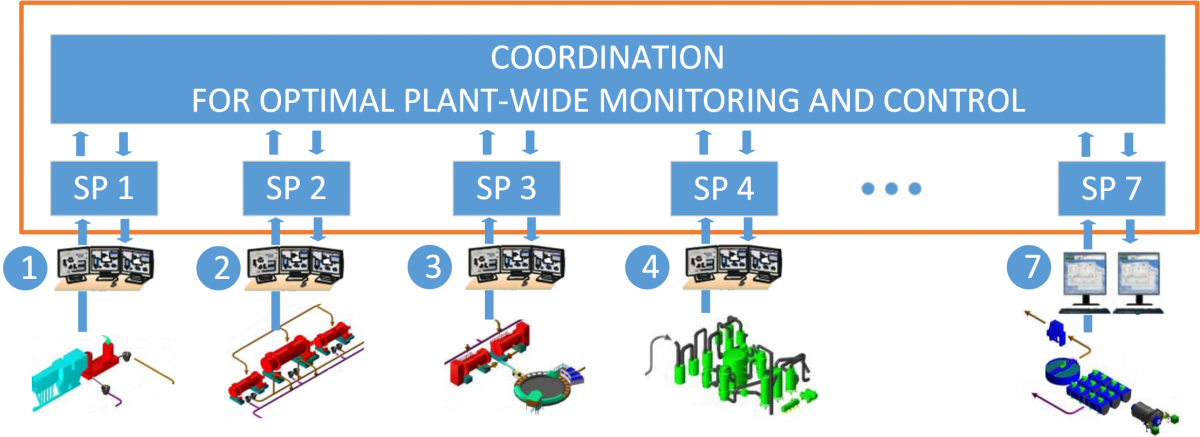

The objective: to enable plant-wide monitoring and control by using the model-based, predictive, coordinating optimisation concept in integration with local control systems.

The approach: the COCOP project’s concept is based on the decomposition-coordination optimisation of the plant operations: the overall problem is decomposed into unit-level sub-problems, so then the solutions of sub-problems are coordinated to plant-wide optimal schedule using high-level coordination. This will enable operators to understand the functioning of the plant as a whole, including the areas traditionally beyond their control, and take better decisions within their part of the process.

The COCOP consortium will research and demonstrate this concept on two pilot cases (copper and steel manufacturing process) and analyse the transferability to other two sectors: the chemical and water treatment processing.

COCOP project will also combine the technological development with a social innovation process of co-creation and co-development for improving effectiveness and impact of the innovations, their implementation process and the related organisational and personnel development.

The Beneficiaries (automation solution suppliers and Process Industry) and benefits: the use of the solution of the project will allow plant operators to approach optimal production and result in reduced operation costs, reduced energy and resource consumption, and decreased on-site material handling time and greenhouse gas emissions,..