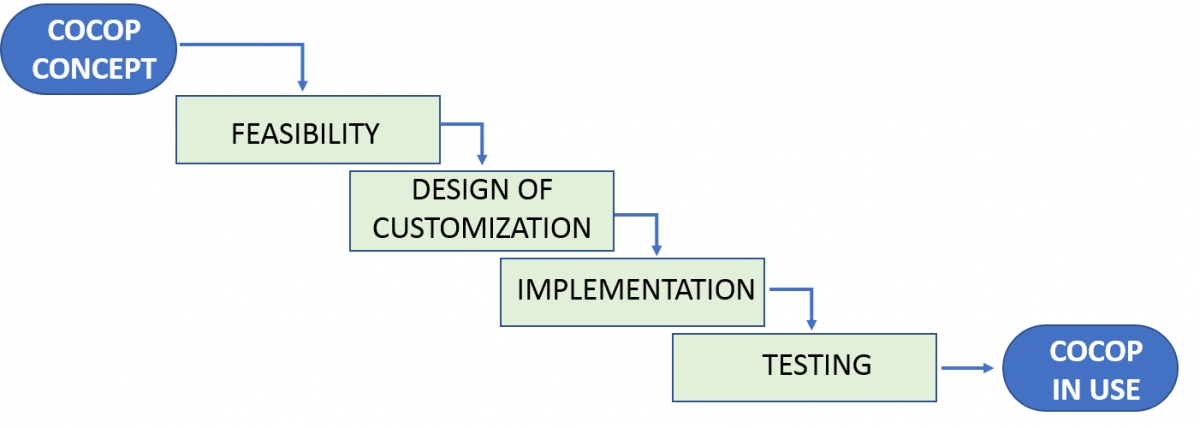

The COCOP implementation workflow

By Jouni Savolainen (@jsavolainen74, https://www.linkedin.com/in/jouni-savolainen-135840/)

One major development in the COCOP project is the implementation workflow. Or, in other words: what needs to be done when the COCOP concept is taken into use at a plant? To put it shortly, COCOP implementation is a process automation delivery project. With a twist or two.

A typical process automation delivery proceeds with through steps like, preliminary, basic and system designs, implementation, installation, commissioning and system acceptance. The work in COCOP strives to identify what twists to this flow of events are necessitated. We do this by observing and learning from our own work.

The very first consideration is to determine whether the COCOP approach is needed at all! If the challenge faced at the plant has characteristics like involving several sub processes with interconnections and contradictory targets as well as having a dynamic nature, then COCOP approach is suitable. These characteristics stem from the underlying plant-wide decomposition-coordination view that the COCOP approach takes. A post by Matti Vilkko about the concept is found here.

Now, since the COCOP concept relies on modelling, this naturally has an effect on the workflow. Suitable models need to be constructed, somehow. Basically, two approaches exist for the modelling. One can construct the models from scratch or alternatively use existing models. The latter, so called Legacy Models, have typically not been constructed for online process control and need to be modified to suit the COCOP concept. For example, a computationally heavy model may have to be simplified. Alternatively, a legacy model may not calculate all that the COCOP concept requires and thus needs to be upgraded.

Likewise for optimization. The COCOP approach is an optimal control approach; it involves defining and solving a mathematically rigorous optimization problem. This definitely is an issue to be considered right from the start of the workflow. Formulation of the optimization problems and their solution is considered its own work package of the project.

In the end, the sophisticated COCOP approach may be useless if nobody at the plant uses it. To avoid this, we are putting an emphasis on human factors research. The goal of this research line is twofold. Firstly, identify issues that need to be considered and secondly, draft an action plan. This action plan is a collection of human factors actions that need to be undertaken. These actions are put on a timeline of the delivery project and responsible people are identified.

This post highlighted a few twists that the COCOP approach brings to a traditional automation delivery project. More are on the way as the COCOP project proceeds towards pilot implementations. These and other related issues are delved into as part of the modelling work package and especially in deliverable 4.4. This document is available for the Special Interest Group members, so join here! A note though, the deliverable is pretty long so a quick video summary of it is also available here. Just to get you oriented.

We at the COCOP project call upon you, the reader, to comment, give feedback, and criticize the topics above. The work is not complete yet and we would love to hear from you!

Follow the discussion in the COCOP Debate Group of Linkedin