Online LCA models enable daily process optimisation in terms of environmental impacts

By Tiina Pajula from VTT (www.vtt.fi)

According to the International Energy Agency, the iron and steel industry are one of the biggest sources of CO2 emissions globally (IEA Clean Coal Centre, 2012). Copper smelter sites are big SO2 emission sources. Both manufacturing industries addressed in the COOCP project have potential to reduce their total CO2 and SO2 emissions by optimising their sub-processes.

Resource efficiency is not only a key factor for sustaining competitiveness, but also for minimising negative impacts on environment. Businesses need to take a step forward to become more resource efficient to reach environmental responsibility and trust within the stakeholders, and encourage the development and implementation of more resource efficient technologies. Developing processes and technologies which enable a lower carbon footprint along the value chain and which facilitate a more circular economy are core business (World Economic forum, scoping paper: mining and metals in a Sustainable World, Feb. 2014). The European Union has taken action by issuing a roadmap to become a more efficient in resource use in Europe. The Roadmap to a Resource Efficient Europe defines resource efficiency targets to the European Union and a plan to achieve them. (Roadmap (Communication COM(2011) 571).

The basic principle of resource efficiency is to measure inputs of materials and energy relative to the physical outputs (more from less – thinking). However, resource efficiency is not limited to company’s boundaries like process and plant management. Instead, it is based on life cycle thinking accounting all the steps from raw material acquisition to the end of product life. To assess the environmental impacts through a life cycle of a product or service a standardized Life Cycle Assessment (LCA) methodology is developed (ISO 14040-44: 2006).

A key performance indicator (KPI) is a type of performance measurement that evaluates the success of an activity. Most companies monitor their energetic and material efficiency and report KPIs normally in retrospect over extended periods of time (e.g. per business year). KPIs reflect, for example, the choice of raw materials, the plant technology used and the operational performance. As such, they cannot support decision-making processes in daily plant operations.

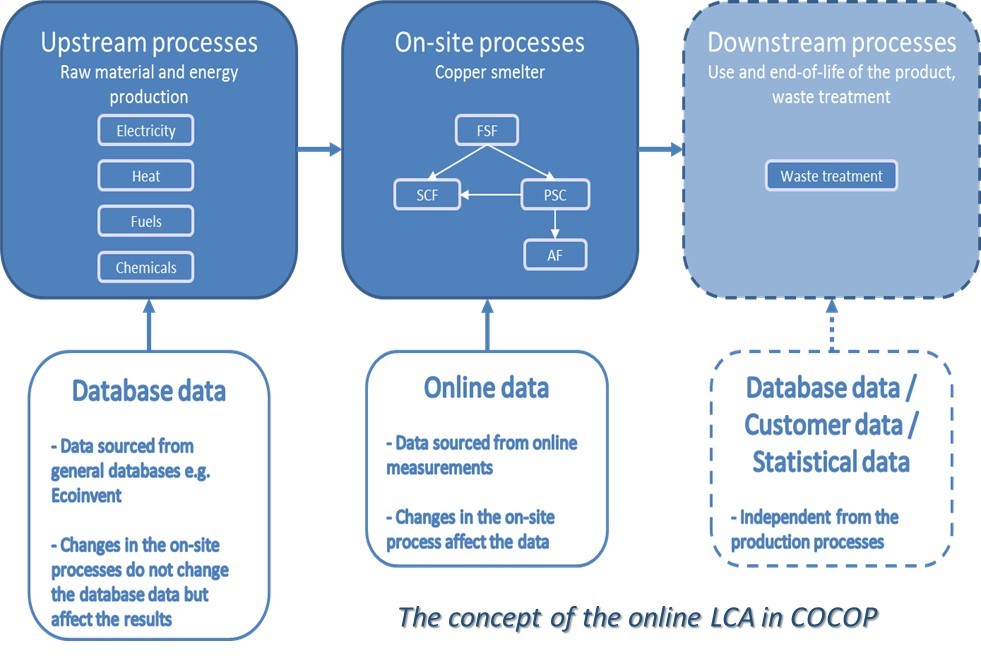

Real-time KPIs are different from KPIs obtained from historic analysis, because they allow online monitoring and rapid intervention to improve resource efficiency. In the COCOP project the use of resource-efficiency indicators is extended by processing and combining the real-time data that is available in the control systems to LCAs, providing model-based decision support to plant operator and managers. The idea is to use the online LCA models to predict the environmental effects of the plants operational level. The benefit is twofold: online data gathering system saves time and improves the reliability of the collected data and at the same time is a quick way for operators and engineers to understand environmental impacts of the daily operative decisions.

Follow the discussion in the COCOP Debate Group of Linkedin