The Low-Carbon Industry

By Jose Ignacio Barbero from TECNALIA (www.tecnalia.com)

To limit global warming to below 2°C and to close as possible to 1.5 °C, the world must reach net-zero CO2-emissions by 2050 [1].

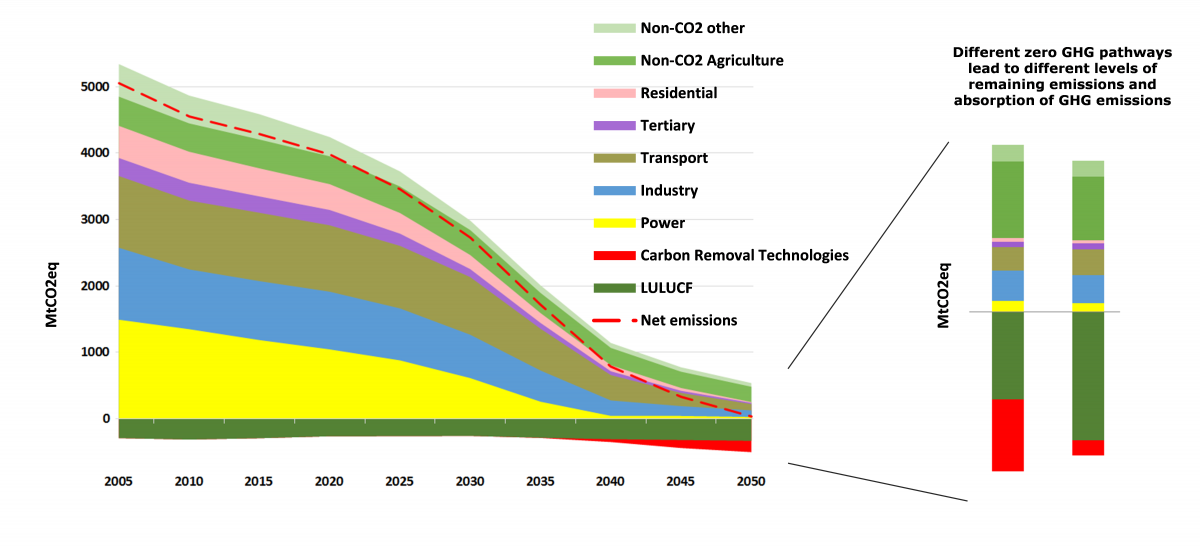

In this sense, the European Council adopted already in 2011 the EU objective of reducing greenhouse gas emissions by 80-95% by 2050 compared to 1990 [3]. The EU-long-term strategy towards 2050 (see figure 1), which was published in 2018 [4], states that for the industry to become greenhouse gas emission free will mean significant modernisation of existing installations or replacement.

Figure 1. GHG emissions trajectory in a 1.5ºC scenario[4].

The production of the Energy Intensive Industries (EII) such as steel, cement and chemical are focused on in the EU-long term strategy. These sectors dominate industrial emissions and the scale-up of already known technologies in the next 10 to 15 years is the objective for the strategy.

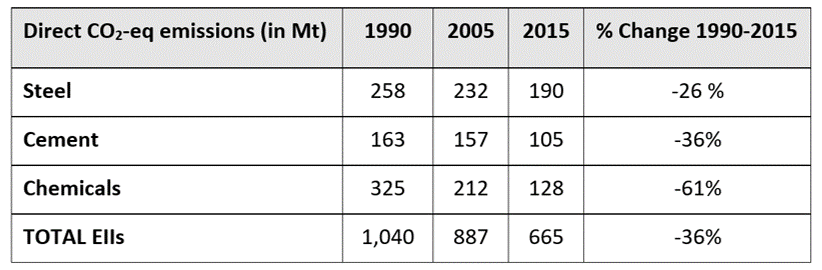

In 2015 the EIIs represented 15% of total direct greenhouse gas emissions (GHG) in the EU [2]. EIIs reduced their greenhouse gas emissions by 36% between 1990 and 2015 (-375 Million Tonnes) and accounted for 28% of the total economy-wide emission reductions by the EU. The following table shows the development of the CO2-emission reductions for the different sub-value-chains:

Table 1: Evolution of direct CO2-emissions for Steel, Cement and Chemicals in the EU [2]

There are multiple options for low-CO2 technologies and the main pathways applicable to most industries include [2]:

- Energy efficiency and energy savings

- Alternative feedstocks/fuels (low-CO2 hydrogen-based / biomass)

- Process integration

- Electrification of heat and processes

- Carbon Direct Avoidance (CDA)

- Carbon Capture and Utilisation (CCU)/CO2-valorisation

- Carbon Capture and Storage (CCS)

- Recycling, materials efficiency and circular economy

- Higher valorisation of waste streams and materials efficiency

In addition, the road to a net-zero greenhouse gas economy could be based on joint action along a set of different main strategic building blocks. One of these blocks is “A competitive EU industry and the circular economy as a key enabler to reduce greenhouse gas emissions” [4], where digitalisation and automation are seen in the short term as some of the more promising and effective avenues to increase competitiveness, leading both to efficiency gains and to greenhouse gas reductions.

The COCOP project focuses on this block increasing product quality and reducing operating costs, energy consumption and environmental footprint of the process industry, through plant-wide monitoring and control by using the model-based, predictive, coordinating optimisation concept in integration with plant’s automation systems.

The COCOP general concept can be applied to any large industrial production site because it relies on general methods such as modelling of dynamics, data analysis and optimization, but the project is demonstrating the concept on two pilot cases (copper and steel manufacturing process) and analysing the transferability to other two sectors: the chemical and water treatment processing.

[1] Energy Transitions Commission 2018. Mission Possible: Reaching Net-zero carbon emissions from harder-to-abate sectors by mid-century

[2] Wyns T, Khandekar G and Robson I. 2018. Industrial Value Chain. A Bridge Towards a Carbon Neutral Europe. (Vrije Universiteit Brussel (VUB) - Institute for European Studies)

[3] Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee of the regions 2011. A Roadmap for moving to a competitive low carbon economy in 2050: COM(2011)0112 final

[4] European Commission 2018. A Clean Planet for all. A European strategic long-term vision for a prosperous, modern, competitive and climate neutral economy: COM (2018) 773 final

Follow the discussion in the COCOP Debate Group of Linkedin