Key Performance Indicator (KPI) and impact evaluation in distributed production systems – The importance of feedback

By Roger Ivaska and Peter Lingman (www.optimation.se/en)

In the design and maintenance of plant-wide control and advisory systems, measuring system performance is fundamental.

Firstly, measurements are needed to design feedback loops and reliable and optimal recommendations to personnel. Secondly, it is important to be able to quantify the improvement obtained with the system in order to justify the investment. Using Key Performance Indicators (KPIs) as part of the plant-wide control solution is gaining interest in the automatic control community.

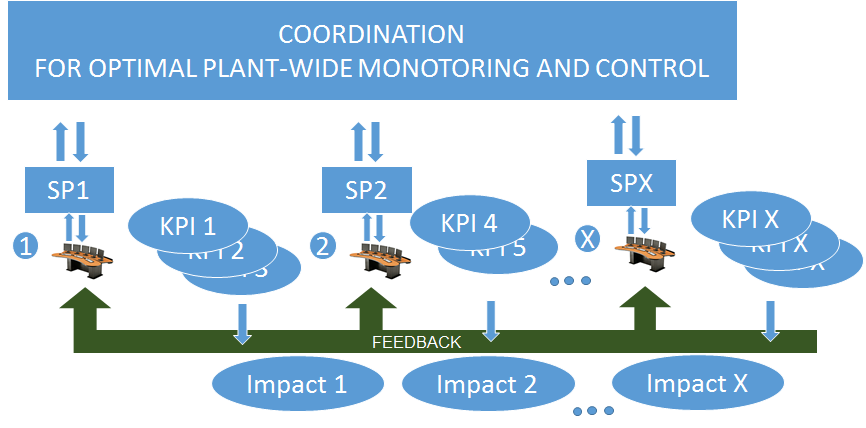

Well defined KPIs can be used as feedback to show the benefits of a plant-wide solution. Feedback can come in many forms. It appears in control loops, daily information to the personnel and measured impacts of improvements. The challenge is to define reliable and trusted KPIs and to distribute the plant-wide information. The information could also be tailored to fit the context even though the defined various process impacts are of the same kind. The idea in COCOP is to have a few well defined KPIs that you can evaluate and to avoid information overflow to e.g. operators.

In a survey published by MESA [1] it is concluded that companies that manage to substantially increase their financial metrics, these companies are sometimes called "business movers", typically have very well defined KPIs, have informed employees and have IT-systems that support generation and distribution of KPIs to personnel that actually can act on the information. In another work presented by Bauer 2016 [2], KPIs are derived and used as the interface between production scheduling and control, i.e. integration using estimates from the planning system and comparing them with actual values from the control system. KPIs are calculated in both systems (production and control) and then fed back to each system for further action. The connection can be loose or strong depending on the application/process.

Concluding that feedback is of importance for successful operations, the question is how do we design the feedback? In the COCOP project we have applied an approach that combines interviewing of plant personnel and using the ISO 22400 standard for KPI design in the manufacturing industry. In addition to technical and economic aspects we have also considered social aspects and the development process itself.

Figure 1: Feedback for optimal plant-wide monitoring and control.

During the last years a standard for calculating KPIs has emerged, ISO 22400 [3]. This ISO standard has been developed mainly for the manufacturing industry (also called discrete production) and not for process industries (also called continuous or batch). The ISO 22400 standard has however been used and modified, see [4], to fit the needs of continuous or batch processes.

COCOP project has followed the ISO standard in order to define the KPIs and the relevant impact evaluation criteria to measure the success of the COCOP implementations at the project pilot sites: Boliden (copper production) and Sidenor (steel production).

Three different sets of Key Performance Indicators (KPI) have been defined: technical, social and development. This differentiation brings a structure to the KPI definition and also simplifies the exchange of KPIs between different process industries and departments within these industries. As far as possible KPIs defined in ISO 22400 have been used, sometimes modified to fit the needs of processes industry. Impact evaluation methods in the COCOP project are relative to baseline, during test periods and in the end of project. For more details, see the deliverable D2.2. Impact evaluation criteria.

Each defined KPI can contribute to one or several top level impacts achieved with the COCOP implementation (like energy usage or CO2 emissions) and the KPIs can be viewed as clear and understandable process feed-back that contribute to the overall equipment effectiveness and environmental goals of the production process.

To derive well-functioning KPIs it is important to focus on process functionality. Equally important is to define the KPIs in such a way that they communicate unambiguous information and that they are used in the right context depending on personnel.

References:

-

(2010). MESA 2010 survey - metrics that matter. Retrieved November 2016 from http://www.mesa.org.

-

(2016). KPIs as the interface between scheduling and control. 11th IFAC Symposium on Dynamics and Control of Process Systems, including Biosystems, NTNU. Trondheim, Norway.

-

(2014). ISO 22400-2 Automation systems and integration - key performance indicators (KPIs) for manufacturing operations management - Part 2: Definitions and descriptions.

-

(2012). Key Performance Indicators - Continuous Process Industry. Report Perstorp AB.

Follow the discussion in the COCOP Debate Group of Linkedin