The Beauty of Automation System Architectures

By Petri Kannisto and David Hästbacka from Tampere University of Technology (http://www.tut.fi)

In the modern world, industrial enterprises must constantly improve their efficiency for multiple reasons.

For instance, due to the intensely competitive, globalised industry of today, inefficient enterprises do not survive. In the utilisation of raw materials, energy or labour resources, any improvement enhances the market position of an enterprise. On the other hand, the growing environmental awareness raises concerns related to the environment, which has led to the goal of reducing emissions. Thus, the optimisation of production is an essential activity. Fortunately, the optimisation task has recently become easier due to ever-developing software tools.

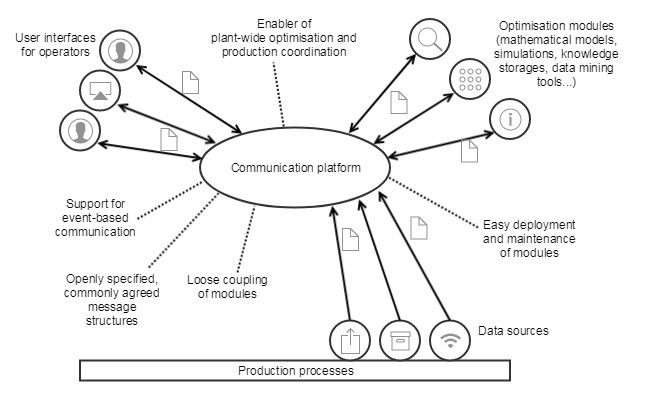

Software systems facilitate production optimisation and the related information management tasks, but they also require careful design related to system architectures. Architecture design is important in the engineering of complex systems, because complexity complicates the overall management of design (Clements et al., 2003, p. 1). Certainly, such complexity appears in large-scale industrial plants. Some plants, such as copper or steel refineries, run multiple unit processes that may be located dispersed from one another. Each unit process may even have its dedicated control room, which is a barrier from the communication point of view. Therefore, to optimise such a production plant, multiple aspects must be considered. Rather than optimising each unit process alone, the software architecture should also enable the coordination and mutual communication between the various facilities of the plant. Besides, the enterprise-level business should also be considered, such as logistics and the related material flows. Fortunately, these various demands are met with an appropriate architecture design. Such design may enable solutions for various requirements, including timely communication, the application of existing production-related knowledge, the discovery of novel knowledge and straightforward systems integration. The architectural aspects of an efficient communication platform are illustrated in the following figure.

The actual optimisation is performed with multiple mutually connected modules that utilise production knowledge. They help operators make appropriate decisions, so that the plant operates in an efficient way. For this, various types of tools may be utilised. For instance, mathematical models may mimic process dynamics to estimate which control actions are suitable for each situation. For such estimation, simulation is a common method. There may also be knowledge storages where production-related knowledge is documented explicitly in a machine-processable format. Furthermore, data mining tools help discovering information in the measurement data collected from production processes. However, although the aspect of correct process operation is essential, the optimisation modules must also be interconnected.

The communication between production-related systems, optimisation modules and operator interfaces is enabled with appropriate communication protocols and message structures. The communication protocol should enable flexible communication with messaging patterns. For instance, event-based communication may be required, as some situations may require timely, correct reactions from the operators. In addition, the communication protocol should enable loose coupling to hide the inherent platform-specific details of each module. Due to loose coupling, module-related dependencies are minimised, which facilitates deployment and maintenance of the modules. On the other hand, message structures are also important. Openly specified message structures should be favoured for two main reasons. First, they may considerably save design effort by reusing existing specifications. Second, compared to vendor-specific interfaces, common agreements eliminate the need for repeated mapping between proprietary formats.

To conclude, carefully designed system architectures are enablers for advanced functionality to make sure that production systems are efficient, adaptable and optimisable in terms of resource consumption and produced quality. This is a result from facilitating communication between production systems. Then, the systems become mutually aware even if they span beyond one facility. An appropriate architecture largely contributes to the utilisation of both existing and future knowledge, and effort is also saved in the design and maintenance of systems. Architectures facilitate reaching various sustainability goals, including saving natural resources and reaching a cleaner environment. Therefore, while system architectures are important in any ICT application area, industrial automation is a domain where an appropriate architecture likely has tangible results.

References: Clements, P., Bachmann, F., Bass, L., Garlan, D., Ivers, J., Little, R., Nord, R., and Stafford, J., Documenting software architectures: views and beyond. Pearson Education, 2003.

Follow the discussion in the COCOP Debate Group of Linkedin